· Rated Current : 16A、20A、25A、32A、40A、45A、50A、55A、60A、63A、65A、70A、80A、85A、90A、95A、100A、125A

· Number Of Poles : 3P/4P

· Rated Working Voltage : 400V/690V

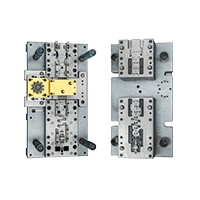

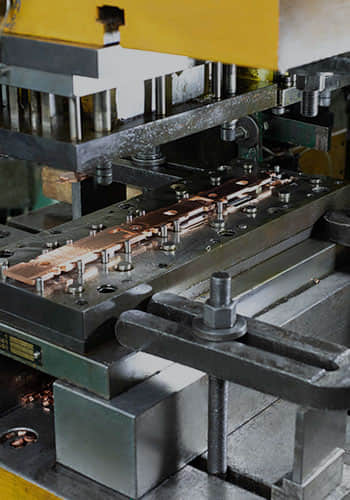

First of all, I would like to emphasise that the price is definitely proportional to the quality. If you are a buyer, you must know that the materials and treatment processes used in our products are better than those of our peers, and the quality is recognised in the same industry. Our factory has a thermosetting workshop, thermoplastic workshop, welding workshop, hardware stamping workshop and assembly workshop, and the rate of self-made parts is as high as 80%. We have also built a new factory in Wuhu to guarantee the supply of parts for us, so that the parameters and various technical indicators such as mechanical life, Icu, Ics, etc. are very stable, and the match between parts is very high, and the service life of the finished product is also very long, which is They can be used in high-end industrial areas and hospitals, where the quality of the circuit breakers is very high. We also have our own technology patents and a very professional R&D team of 30-40 engineers to respond to the various needs of our customers, the development cycle of new products only takes 30-40 days, in the process, unconditionally provide you with technical expenses, we can greatly reduce the cost of communication and research and development costs. if particularly urgent, I can apply to my superiors to set up a customer line for you, specifically for you to assemble MCCB.

We have not worked directly with foreign customers before, we provide ODM and OEM services for brands in China and then they take our products and sell them to foreign customers, basically to Europe and the Middle East.

We have a incoming inspection for the raw material and process inspection for the rivet and stamping. There is also final statistical audit which consisting the measurement of sizes, tensile test and coat examine.

Our total area is 7000 square meter. We have 300staffs, .40 engineers.

We can produce 3000 sets per month.

It varies according the different kinds of product. We can negotiate it before place an order.