Date | 2022-09-05 13:00:49

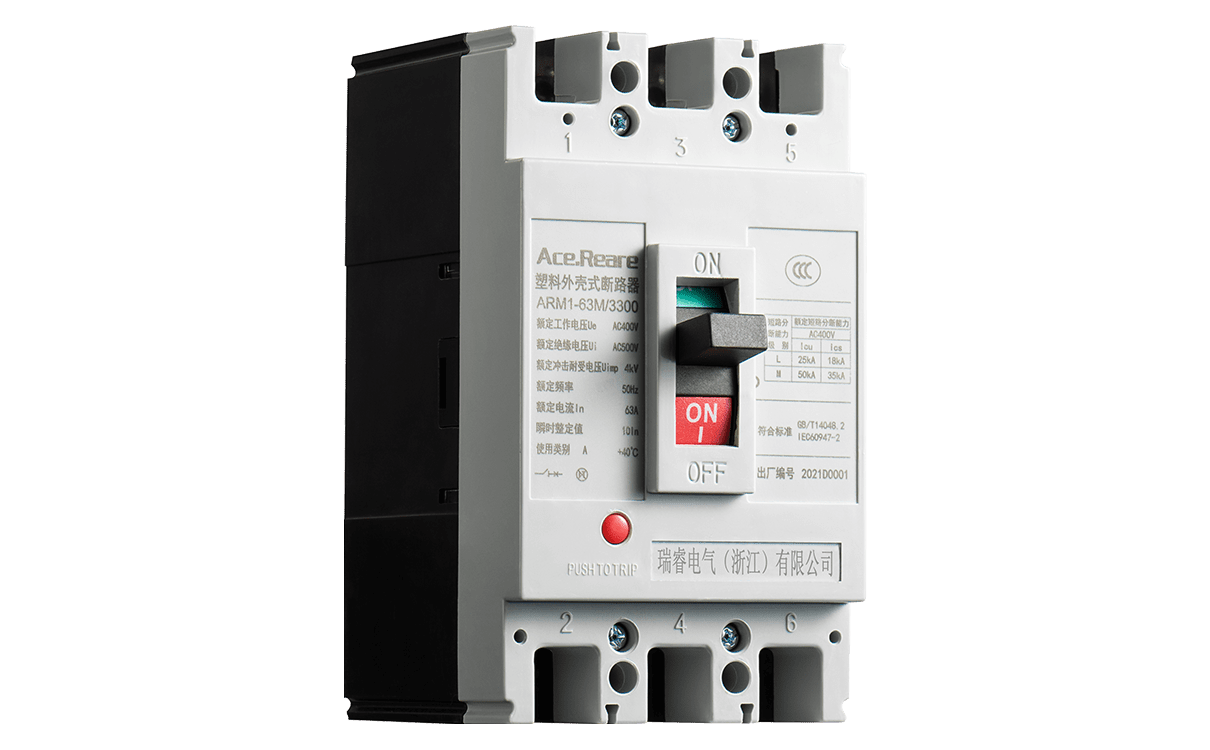

Moulded case circuit breakers are one of the most widely used protective items in our daily lives. In the selection and use, if you do not understand the technical performance and use of the environment, it often leads to waste and often even accidents. So let's take a look at the specific methods and precautions for choosing a plastic-case circuit breaker?

A, the scope of application and use of plastic case circuit breakers

Plastic case circuit breakers are suitable for rated operating voltage 690V , frequency 50/60Hz, rated output current 16 ~ 1600A distribution management system or used as transformers, motors, capacitors and other protection equipment plastic case circuit breakers as the main development, the role in the distribution of electrical energy can be used for a variety of branches and electrical safety equipment overload, short circuit, leakage and under-voltage protection, can also be used to control the line and infrequent conversion of electrical information equipment.

Second, the selection method of molded case circuit breaker

According to the type of load: mainly divided into distribution system and motor protection.

According to the load capacity: the rated current of the selected moulded case circuit breaker is greater than the load working current.

According to the different short-circuit current, you can choose: the impact of the short-circuit breaking capacity of the rated working operation of the molded-case circuit breaker is greater than the circuit current value of the expected short-circuit line design. The development of the short-circuit breaking capacity of the moulded case circuit breaker determines the reliability of the circuit breaker, but in the case of ensuring the safety of the route of travel, it is not necessary to pursue a high breaking capacity, otherwise it will result in wasted resources.

Notes on the selection of plastic housing for circuit breakers

1. The difference in breaking capacity

There are two important indicators of the breaking capacity of plastic-case circuit breakers: the rated operating short-circuit breaking capacity ICS (specified conditions in the prescribed experimental procedures), including the breaking capacity of the plastic-case circuit breaker to continue carrying its rated current) and the rated current capacity. The ultimate short-circuit breaking capacity ICU (specified conditions in the test procedure, including the breaking capacity of a moulded-case circuit breaker that continues to carry its rated current capacity). The difference between the two is that the rated short-circuit breaking capacity is the ability of the circuit breaker to act again and disconnect the short-circuit current after disconnecting the three-phase short-circuit current at the outlet. As to whether it can be properly connected and disconnected later, there is no guarantee. The rated operating short-circuit breaking capacity requires that the power supply can be cut off several times under the above conditions.

2. Circuit breaker cooperation

The choice of a single circuit breaker directly affects the choice of the overall accessory lines and line segments of the enterprise. The circuit breaker needs to be selected according to the overall structural components of the information system. In order to achieve different faults at any point of the line, these faults can be eliminated by the adjacent higher level circuit breakers.