Date | 2022-09-05 12:59:31

What is a moulded case circuit breaker? It is a circuit breaker with a plastic case as protection, referred to as a plastic case circuit breaker, also known as an air switch. Suitable for.

1. altitudes of 2000m and below.

2. ambient media for temperatures generally not higher than +40°C (+45°C for marine products) and not lower than -5°C.

3. capable of withstanding the effects of humid air

4. able to withstand the effects of salt spray and oil spray;

5. a maximum degree of inclination of ±25.5°.

6. able to work reliably when subjected to vibrations affecting the normal conduct of the ship

7. reliable operation during earthquakes (4g)

8. no insulating gas or conductive dust sufficient to corrode metals in non-explosive hazardous media;

9. free from rain and snow.

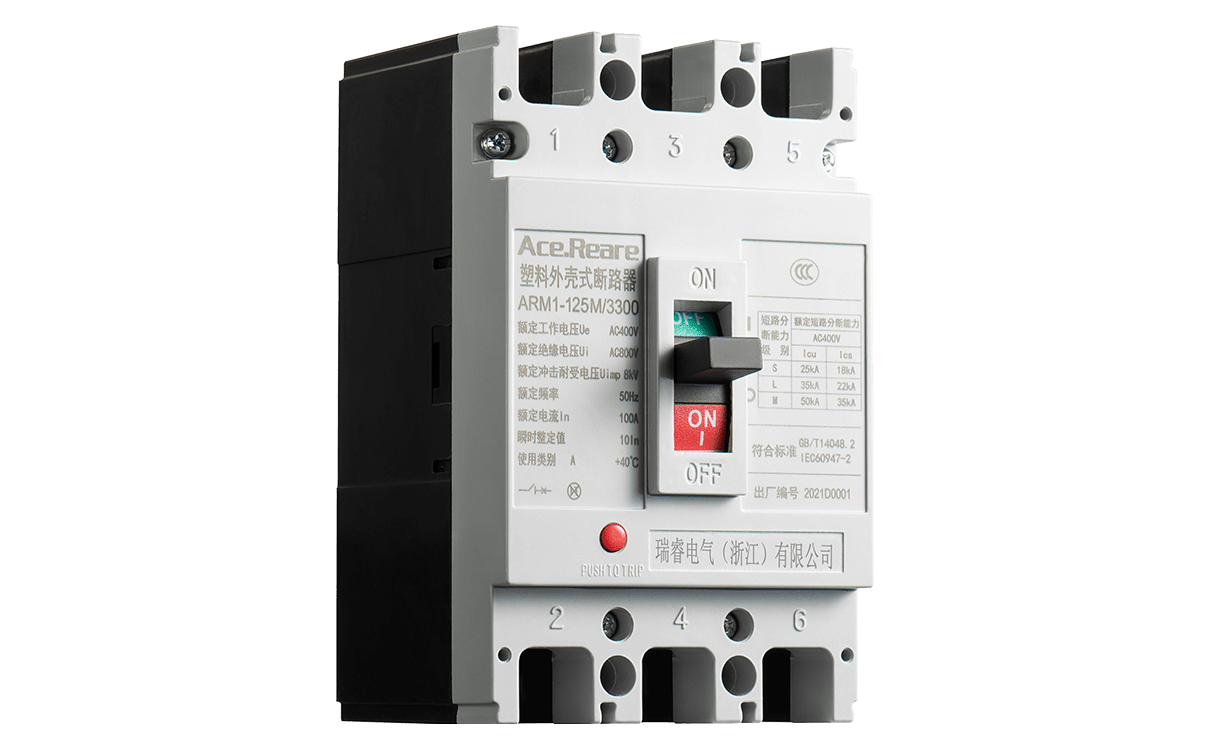

The role of the moulded case circuit breaker is that it can replace the fuse and knife switch and the new products derived from it, no matter how the enterprise products are carried out through improvements and changes, generally in this case have six-link operation management mechanism and no flying arc function, which is the most mainstream air switch circuit breaker necessary in China's current market. Because knife switches do not have the legal protection of the environment function, so the circuit breaker has become a preferred technical product.

TAXI Electric plastic case circuit breakers are divided into three types according to the number of products: single pole (below 63A), three pole and four pole. The neutral pole (N-pole) types of four-pole products can be divided into the following four types.

Type: N-pole not fitted with an overcurrent release device, N-pole always connected, not connected to the other three poles.

(Type B: N-pole not reasonably fitted with overcurrent generating release and N-pole closed and divided with other national tertiary students; N-pole not closed and then divided).

(Type C: N-pole fitted with an overcurrent generating decoupler and N-level combined with other use of three-pole devices; N-pole first combined and then divided).

Type D: N-pole equipped with overcurrent release device and N-pole always connected, not separated from other three poles.

Taisi electric circuit breakers can be classified according to rated current A (class) :

-63 for 6, 10, 16, 20, 25, 32, 40, 50 and 63A in nine classes (6A specification without overload protection).

-100 for classes 10, 16, 20, 25, 32, 40, 50, 63, 80 and 100A; S-3VD3-160 for classes 100, 125, 140 and 160A.

-250 for classes 100, 125, 140, 160, 180, 200, 225 and 250A VIII.

-400 is class 225, 250, 315, 350 and 400A five.

-630 is Class 400, 500 and 630A.

-800 is Class 3 630, 700 and 800A.

-1250 is class 2 of 1000 and 1250A.

The wiring design method can be divided into the following three types: wiring in front of the board, wiring behind the board and plug-in type.

Overcurrent release can be classified by type: thermal - electromagnetic (copy) type, electromagnetic (transient) type.

The structure of the molded case circuit breaker consists of operating mechanism, contacts, protection devices (various decoupling), arc extinguishing system, etc. The main contacts of the formed case circuit breaker are operated manually or electrically. After the main contact is closed, the free release mechanism locks the main contact in the closed position. The coil of the overcurrent release and the thermal element of the thermal release are connected in series with the main circuit and the coil of the undervoltage release is connected in parallel with the power supply. When the circuit is short-circuited or severely overloaded, the armature of the overcurrent derailer is pulled in, causing the free release mechanism to move and the main contact to break the main circuit. When the circuit is overloaded, the hot element of the thermal release causes the bimetal plate to bend due to heating, thus prompting the free release mechanism to act. The armature of the undervoltage release mechanism is released when the circuit is undervolted. It also causes the free tripping mechanism to move. The parallel release mechanism is used as a remote control device. In normal operation the coil is de-energised. When distance control is required, the start button is pressed to excite the coil and the armature drives the free tripping mechanism, breaking the main contact.