Date | 2022-08-30 11:14:04

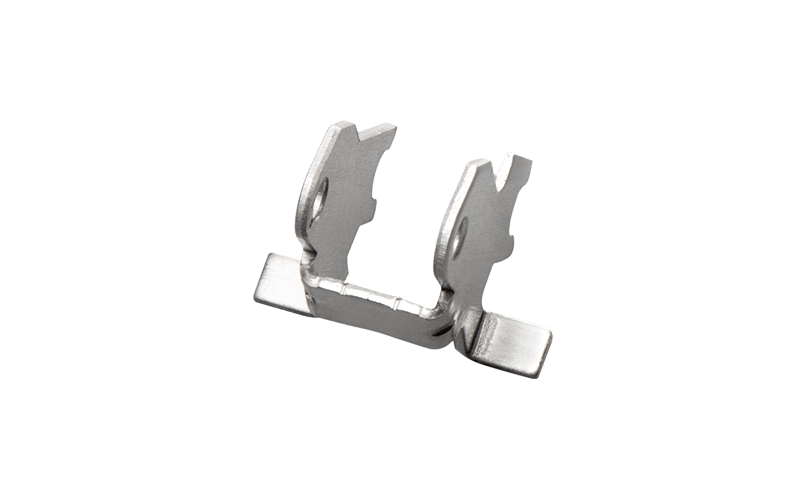

Professional connector buyers must have experience in purchasing hardware stamping parts to know where to start with hardware stamping parts. Next, the engineers of Nanjing connector manufacturers to popularize the hardware stamping parts from where to start. I believe that through the hardware stamping manufacturer's explanation, you will have a deeper understanding of hardware stamping parts.

1, the design of the stamping parts must meet the use and technical performance of the product, and easy to assemble and maintain.

2, the designed stamping parts must be conducive to improving the utilization rate of metal materials, reducing the types and specifications of materials and minimizing the use of materials. consumption. The use of low-cost materials wherever possible and the minimisation of waste of parts.

3. The designed stamping parts must be simple in shape and reasonable in structure, and be conducive to simplifying the structure of the mould and the number of processes, i.e. to complete the processing of the whole part with the least and simplest stamping process, to reduce the processing by other methods, and to facilitate stamping operations. Facilitate the organisation of mechanised and automated production and increase labour productivity.

4. Designing the pressed parts to ensure normal use and minimize the dimensional accuracy grade and surface roughness grade requirements, which is conducive to product exchange, reducing waste and ensuring product quality. Stable quality.

5. The designed stamping parts should be processed with the existing equipment, process equipment and technology as far as possible, which is conducive to prolonging the service life of the stamping dies. After reading the above, you should know to start with the hardware stamping parts. More knowledge about hardware stamping parts design stamping parts must meet the product use and technical performance, and easy to assemble and repair.

(2) The designed stamping parts must be conducive to improving the utilization rate of metal materials, reducing the variety and specifications of materials and minimizing material consumption. Low cost materials are used wherever possible and parts are kept as scrap and blank as possible.

(3) The designed stamping part must be simple in shape and reasonable in structure to simplify the structure of the mould and the number of processes, i.e. to complete the processing of the whole part with the least and simplest stamping process, to reduce the need for other processing methods and to facilitate stamping operations. It facilitates the organisation of mechanised and automated production and increases labour productivity.

(4) For well-designed stamping parts, under normal use, try to reduce the dimensional accuracy level and surface roughness level, which is conducive to product replacement, reduce waste and ensure the stability of product quality.