Date | 2022-08-30 11:12:27

There are many types of metal stamping materials with different characteristics for use. The choice of metal stamping materials for hardware stamping manufacturers should be based on your needs and there are different choices in the design and production process. The design of the correct process is an essential step in our production.

The production of metal stamping drawn parts must follow several design principles.

1. The design of the stamped product must not only meet the original technical properties, but also be easy to assemble.

2. The designed stamping and drawing parts must be able to improve the utilisation rate of metal materials, reduce the consumption and waste of materials and avoid waste as far as possible.

3. The designed stamping and deep-drawing parts should have a simple shape and relatively reasonable structure, which is conducive to simplifying the structure of metal stamping dies and improving production efficiency.

4. When the designed stamping and drawing parts can be used normally, the dimensional accuracy should be reduced, the generation of unqualified products should be reduced and the stability of product quality should be ensured. 5. The designed stamping and drawing parts should facilitate the processing of metal stamping moulds and be conducive to extending the service life of metal stamping moulds.

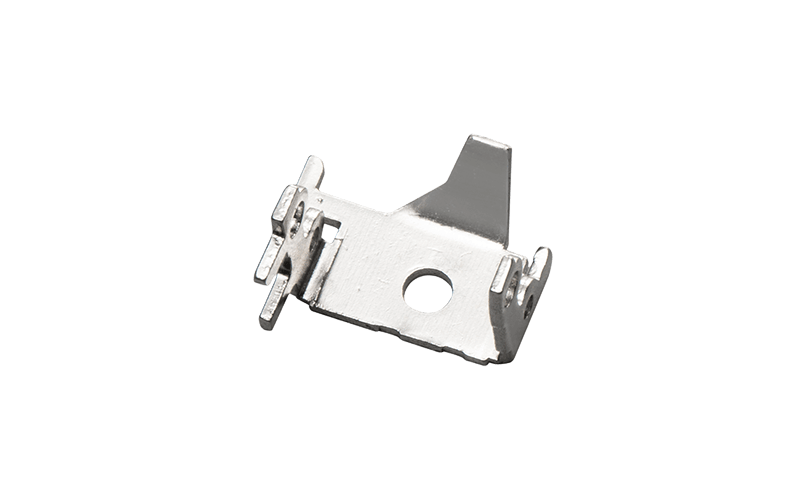

Electrolytic galvanised steel is a cold-rolled steel sheet based on the above three types of cold-rolled steel sheets with surface treatment such as electrolytic galvanisation. Its chemical composition and mechanical properties are similar to those of the cold-rolled steel mentioned above: electrolytic cold commercial steel (SECC). Electrolytic cold-drawn of SECD steel. The materials used in the design of electrolytic cold hardware stamping pads for profiles are mainly SUS301/302/303/403/430 and are mainly used for the manufacture of shrapnel, external decorative parts and parts that require rust protection. Other products, such as bronze and brass, are mainly used for terminals, conductive parts, etc. Design principles When designing product components for sheet metal parts, ease of manufacture must be taken into account. Ways are sought to make machining easier, while saving material and increasing strength without waste. To this end, the designer should pay attention to the following manufacturing aspects. Process issues for sheet metal parts are difficult for stamping, bending and drawing. A good process should ensure low material consumption, few processes, simple tool construction, long service life and consistent product quality. In general, material characteristics, part geometry, dimensions and accuracy requirements have the greatest influence on the manufacturability of sheet metal parts.