Date | 2022-12-08 15:11:19

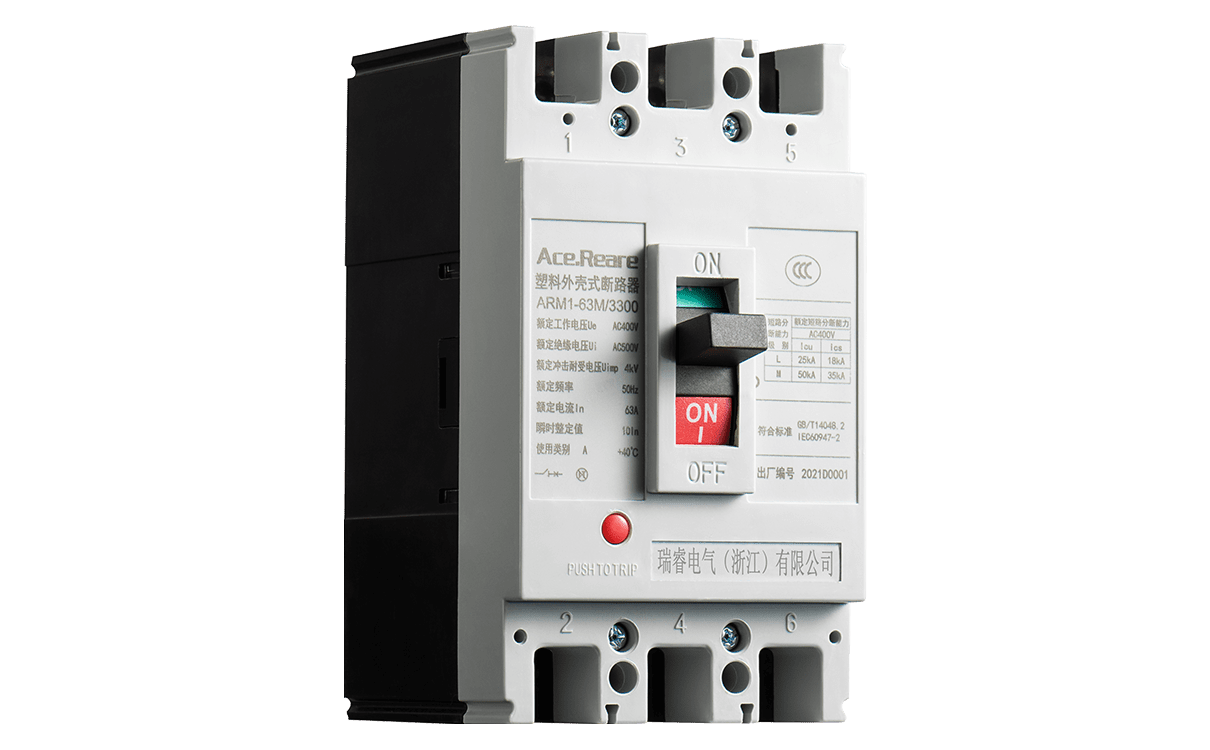

In the molded case circuit breaker used more and more widely today, have you usually paid attention to it? Some customers say it didn't take much time to break down after buying this, there are all kinds of problems, it's really troublesome. In fact, there are only two reasons for this situation.

The first reason may be that the quality of the product you buy is not good enough, in order to save money to buy a poor quality product. The second reason is that they do not know the environment and maintenance methods of the plastic case circuit breaker, the life of the equipment is significantly shortened.

The first reason may be that the quality of the product you buy is not good enough, in order to save money to buy a poor quality product. The second reason is that they do not know the environment and maintenance methods of the plastic case circuit breaker, the life of the equipment is significantly shortened.

Ninety of the contacts of the molded case circuit breaker is manually operated. Of course, people who think that manual trouble can try electric connection. There is also such a function. After the main contact is closed, a freely disengageable mechanism locks the main contact in the proper position. After the decoupler coil, decoupler element and main circuit are connected in series, the machine starts to work. Users can only know how to operate and maintain it if they fully understand its structure.

During normal use of the case circuit breaker, it is noted that when the circuit is short-circuited or overloaded, the over-power release device will cause the armature to adsorb and the free release mechanism to operate, cutting off the main circuit. When the circuit is overloaded, the thermal element may bend and the main circuit may be cut off. If the circuit lacks voltage, the undervoltage striker will release.

Currently, the molded case circuit breaker is very simple to use, and if you buy a quality assured product, there is no need to worry about the subsequent operation. Where it can actually be used, the operator is familiar with the machine. Even if problems arise in use, there is nothing to worry about. It can be repaired according to the instruction manual, or you can just entrust the experts to repair it if you can't get it right. In any case, isn't it better to have a machine that doesn't let the user take the risk?