Date | 2022-09-16 13:41:00

Principle: The tripping position of the metering switch can be monitored by activating the tripping relay. When a metering switch manufacturer trips, its closed circuit returns to a conductive state and then tripping occurs.

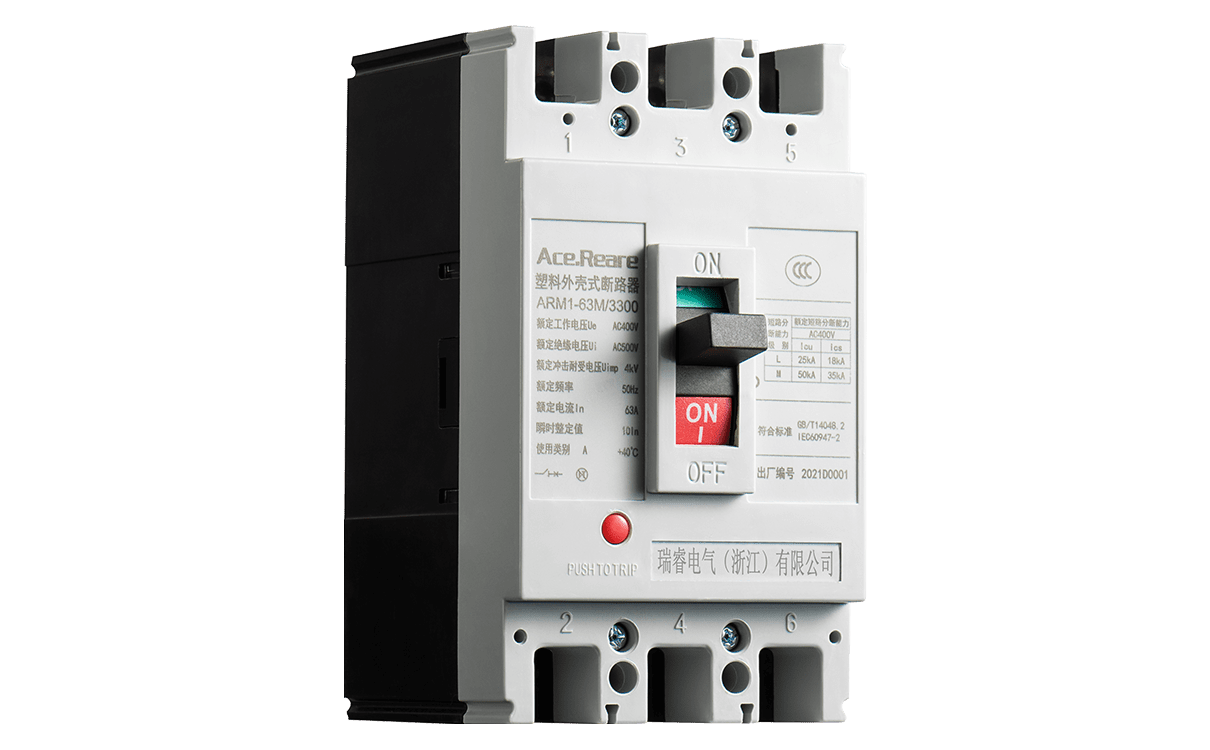

It is a switching device that can turn on, carry and shut off current under normal circuit conditions and turn on, carry and shut off current under abnormal circuit conditions within a specified time period for metering switch manufacturers. Metering switches are divided into high-voltage metering switches and low-voltage metering switches according to their scope of application, and the boundaries between high and low voltage are relatively vague. Generally those above 3kV are called high voltage appliances.

Metering switches can be used to distribute electrical energy, infrequently start asynchronous motors, protect power lines and motors by metering switch manufacturers, and automatically cut off the circuit in the event of a serious overload or short circuit and undervoltage fault. They are functionally equivalent to a combination of fuse type switches and overheating and overheating relays. And they generally do not require replacement parts after opening the fault current. They are now widely used.

Power distribution is an extremely important link in power generation, metering switch manufacturers transmission and use of electricity, the distribution system includes transformers and a variety of high and low voltage electrical equipment, low-voltage metering switch is a large amount of electrical appliances, a wide range of applications.

2. Working principle.

The metering switch is generally composed of a contact system, an arc extinguishing system, an operating mechanism, a decoupling device and an enclosure.

When short-circuiting, the magnetic field generated by the high current (generally 10 to 12 times) overcomes the counterforce spring, the decoupler pulls the operating mechanism into action and the switch is instantly decoupled. When overloaded, the current becomes large, the heat generation intensifies and the bimetal deforms to a certain extent to push the mechanism into motion (the larger the current, the shorter the action time).

For the electronic type, the transformer is used to collect the magnitude of the current in each phase and to compare it with the set value. When the current is abnormal, the microprocessor sends a signal to the electronic decoupler to drive the operating mechanism into action.

The role of the metering switch is to cut off and switch on the load circuit and cut off the fault circuit to prevent the accident from expanding and to ensure safe operation. While the high voltage metering switch has to open an arc of 1500V and a current of 1500-2000A, these arcs can stretch to 2m and still continue to burn. Therefore, arc extinguishing is a problem that must be solved for high-voltage metering switches.

The principle of arc extinguishing is mainly to cool the arc to attenuate thermal dissociation. On the other hand, blowing the arc stretches the arc, enhancing the compounding and spreading of charged particles, while blowing away the charged particles in the arc gap and quickly restoring the dielectric strength.

Low voltage metering switches, also known as automatic air switches, can be used to switch on and off load circuits and also to control motors that are not frequently started. Its function is equivalent to the sum of some or all of the functions of a gate switch, an overcurrent relay, a loss-of-voltage relay, a thermal relay and a leakage protector, making it an important protective appliance in the low-voltage distribution network.

The low-voltage metering switch has a variety of protection functions (overload, short-circuit, undervoltage protection, etc.). It is widely used because of its adjustable action value, high breaking capacity, ease of operation and safety. The structure and working principle of the low-voltage metering switch consists of an operating mechanism, contacts, protection devices (various decouplers), arc extinguishing systems and other components.

The main contacts of the low-voltage metering switch are manually operated or electrically closed. After the main contact is closed, the free release mechanism locks the main contact in the closed position. The coil of the overcurrent release and the thermal element of the thermal release are connected in series with the main circuit and the coil of the undervoltage release is connected in parallel with the power supply. When the circuit is short-circuited or severely overloaded, the armature of the overcurrent striker is sucked in, causing the free release mechanism to act and the main contact to break the main circuit. When the circuit is overloaded, the thermal element of the thermal decoupler heats up, causing the bimetal to bend, thus driving the free decoupling mechanism into action. When the circuit is under-voltage, the armature of the under-voltage decoupler is released. And the free release mechanism is also actuated. The parallel trip device is used for remote control. During normal operation, its coil is p