Date | 2022-08-11 08:50:38

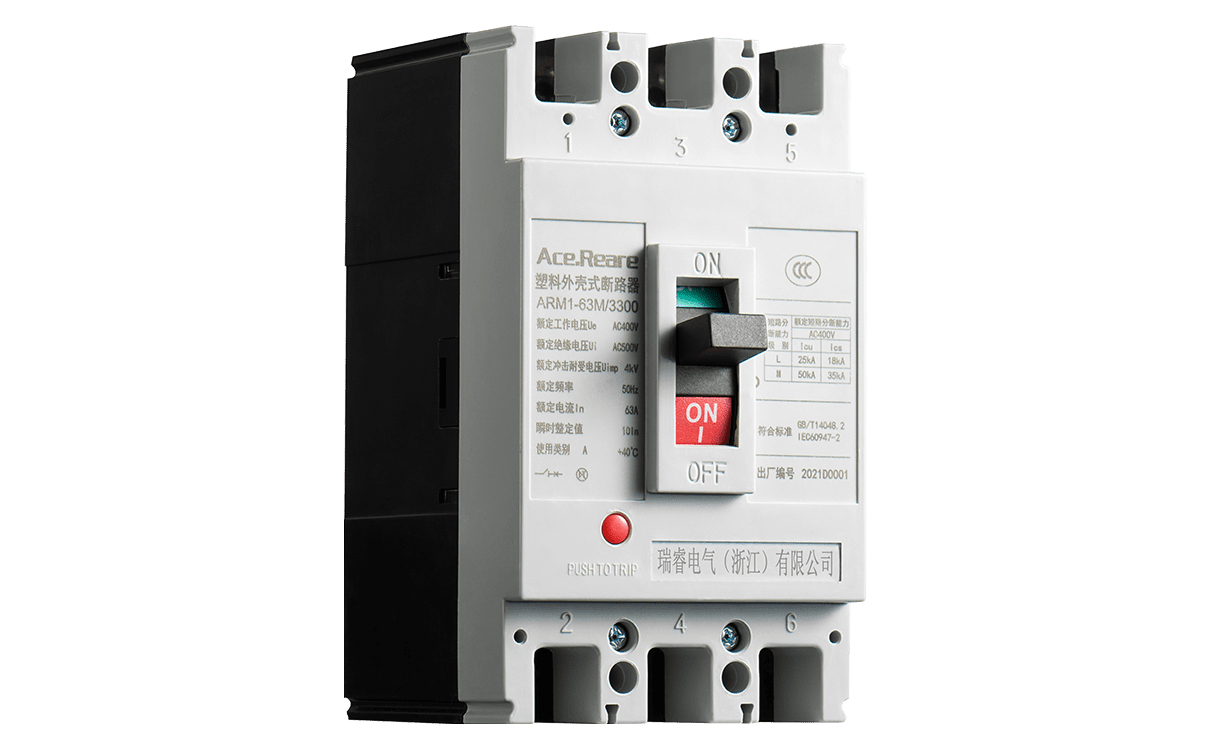

What is a Moulded Case Circuit Breaker

Moulded case circuit breakers, also known as component circuit breakers, have all components sealed in plastic housings, auxiliary contacts, low voltage tripping and parallel tripping. Due to the very tight construction, moulded case circuit breakers are not serviceable.

Due to the use of electronic overcurrent trippers, plastic circuit breakers can be divided into Class A and Class B. Class B offers good three-stage protection, but due to price factors, the mayor/market share is higher for Class A products that use thermal magnetic tripping. Plastic case circuit breakers are a type of circuit breaker. The contacts, digestion chamber, tripping device and working mechanism are mounted on a plastic case. Maintenance is generally not a consideration and is suitable for branch protection. There are two types of overcurrent tripping devices: thermal-magnetic and electronic. Ordinary thermomagnetic plastic case circuit breakers are non-selective circuit breakers with only two methods of protection: overload long delay and short circuit instantaneous. Electronic moulded case circuit breakers have overload long delay, short circuit short delay, short circuit instantaneous and earth fault protection. Some of the newer electronic moulded case circuit breakers also have area selective interlocking functions. Most of the moulded case circuit breakers are manually operated and some are motor operated.

Moulded case circuit breaker operating principle

Interlocking controls are available in both mechanically and electrically driven types. The basic principles of operation are as follows.

(1) Mechanical interlocking devices usually use a wire rope or lever mechanism to make it impossible to activate the working handle of the disconnector until the breaker has changed its mechanical position or the power has been cut off using a multi-functional program lock.

(2) There are two types of actuators. One type controls the handle of the disconnector switch by means of the linked auxiliary contacts (normally open or normally closed) of the working mechanism. The breaker operating handle cannot be moved unless the breaker is open.

(3) The other type of motorised device uses a driven auxiliary contact (normally open contact or normally closed contact) in the distance switch operating mechanism to control the circuit breaker. When the disconnecting switch handle is pulled, the interlocking auxiliary contacts (normally open contacts or normally closed contacts) cut off the circuit through the circuit breaker action to prevent a switch pulling accident with a farther load.

Plastic case circuit breaker role

1. In the normal state, open and close the no-load and load working currents that control the high-voltage system circuit.

2. In the event of a system fault, protection devices and automatic devices can quickly cut off the fault current and prevent the accident from escalating, thus ensuring the safe operation of the system.

Normally, there are no lubrication problems with moulded case circuit breakers; it is usually the operating mechanism that requires lubrication. The function of a thermal relay is to automatically cut off power in the event of a motor overload. The construction of a thermal relay consists of two metal plates with different coefficients of expansion for cutting off the power supply. The thermal relay offers a manual reset and an automatic reset after operation. Fuse operation: In the event of a circuit fault or abnormality, as the current rises, the rising current can damage the circuit with some important or valuable components and may also burn out the circuit or cause a fire.