Date | 2024-09-17 05:01:30

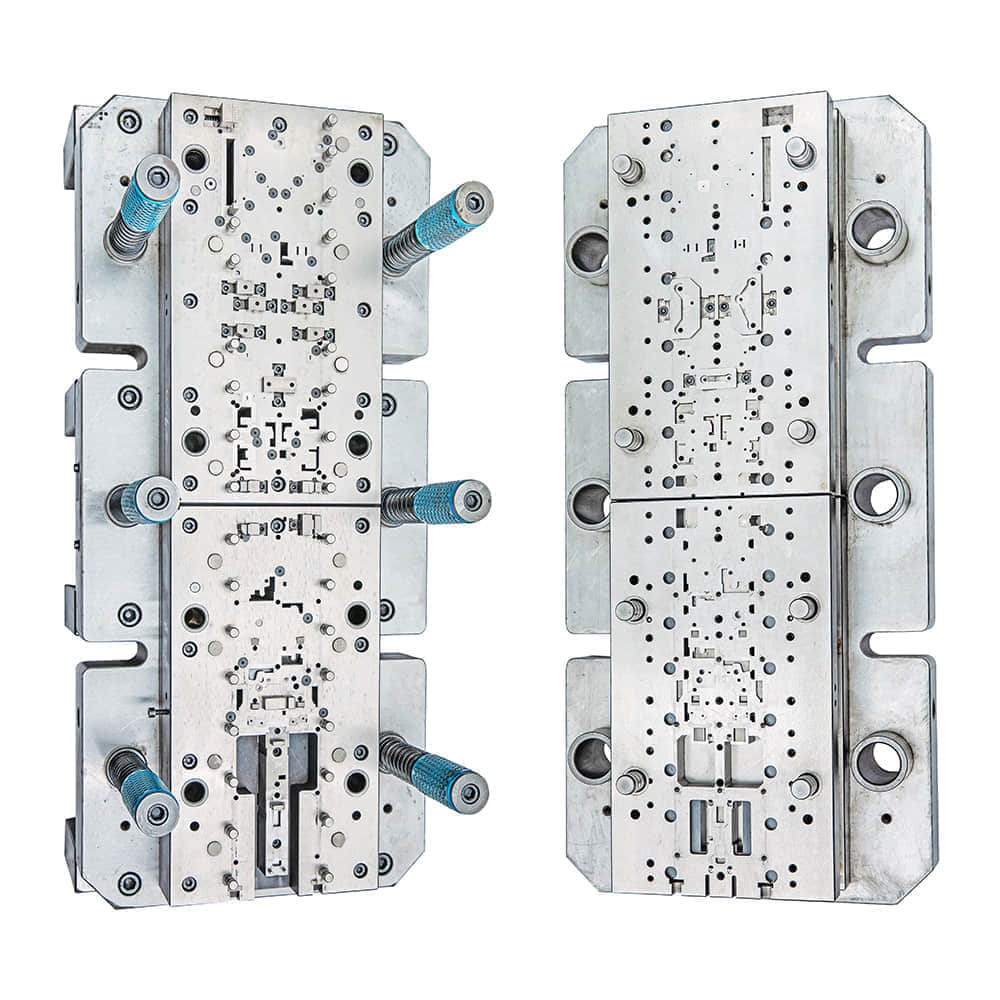

In today’s industrial landscape, the role of a Metal Stamping Die Manufacturer is pivotal, providing essential components that drive efficiency and precision across various sectors. Metal stamping is a crucial process used in manufacturing where metal sheets are shaped into specific forms using dies and presses. This process is integral to the production of numerous products, from automotive parts to household appliances, highlighting the importance of high-quality dies.

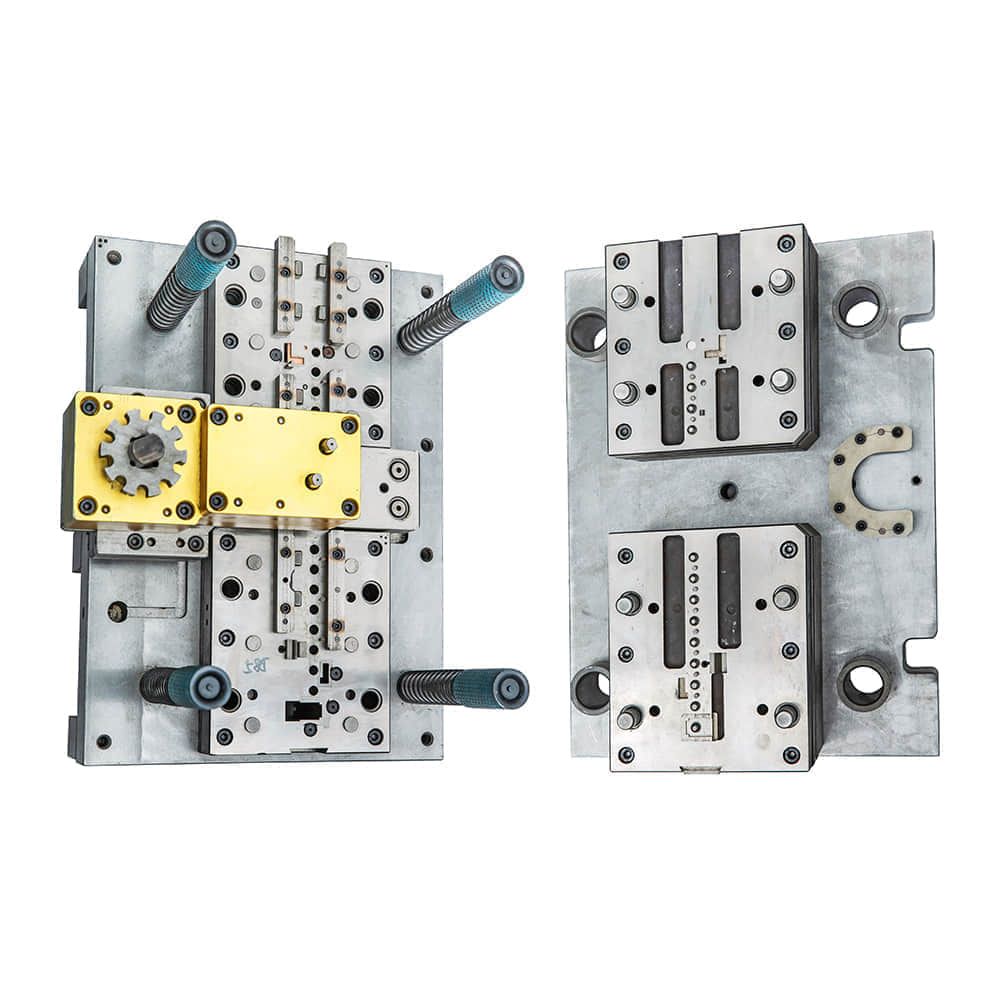

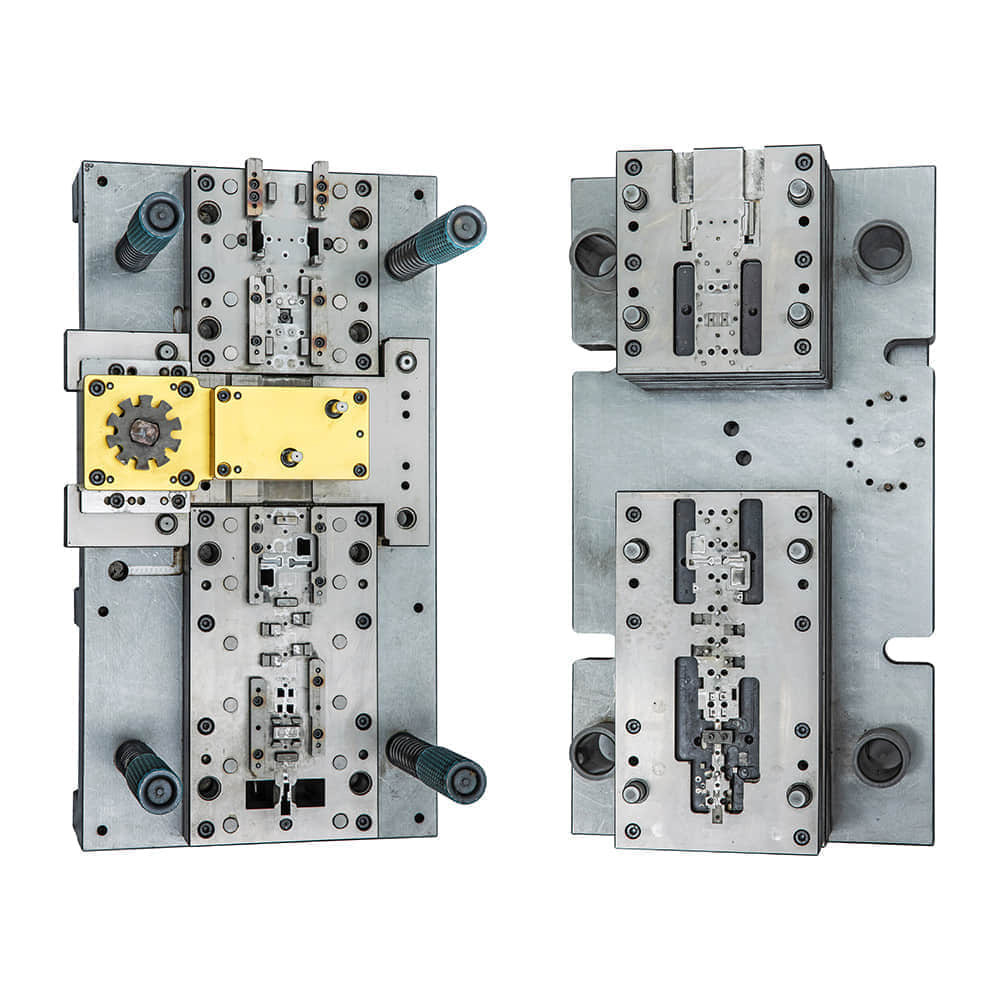

A Metal Stamping Die Manufacturer specializes in designing and producing these dies, which are tools used to cut, shape, and form metal sheets into desired parts. The process begins with understanding the specific needs of a client, which can range from custom designs to mass production requirements. The manufacturer’s role is to ensure that these dies meet precise specifications to achieve optimal results in the stamping process.