the advantages and applications of injection molded parts

Date | 2024-09-17 04:37:18

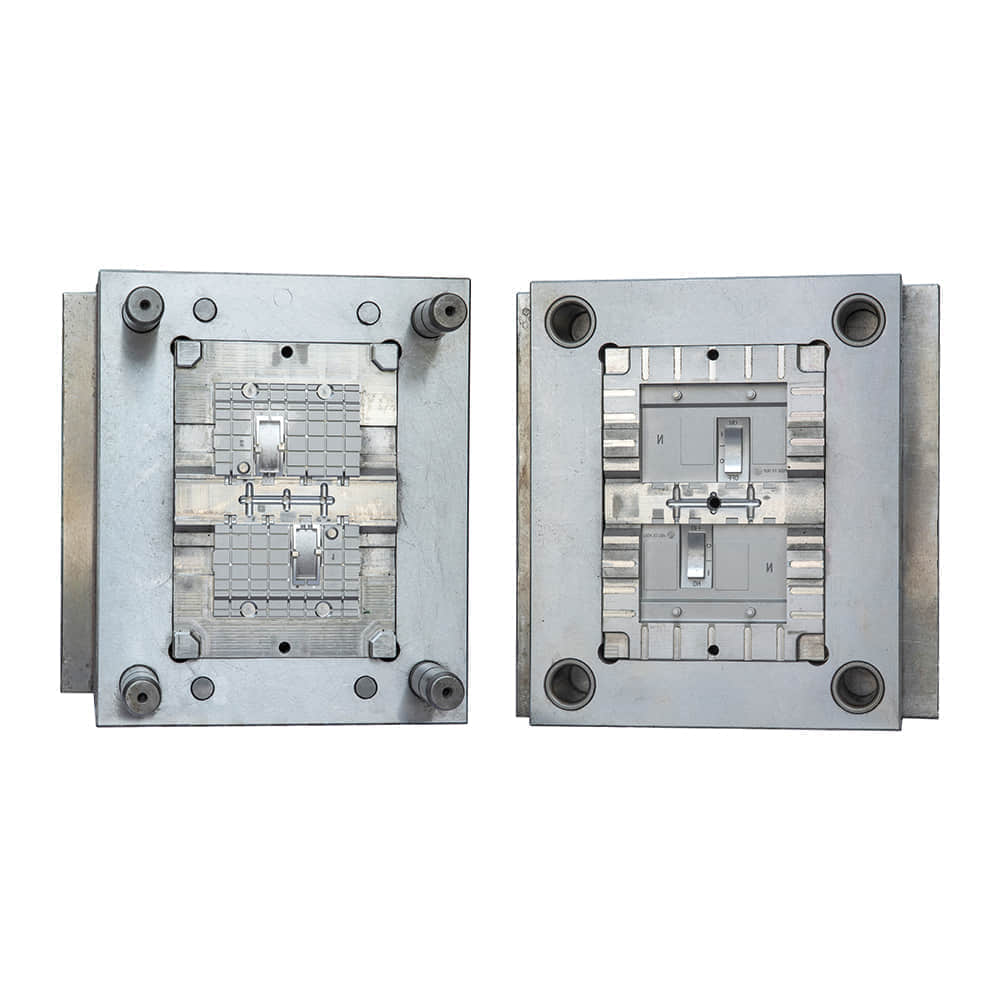

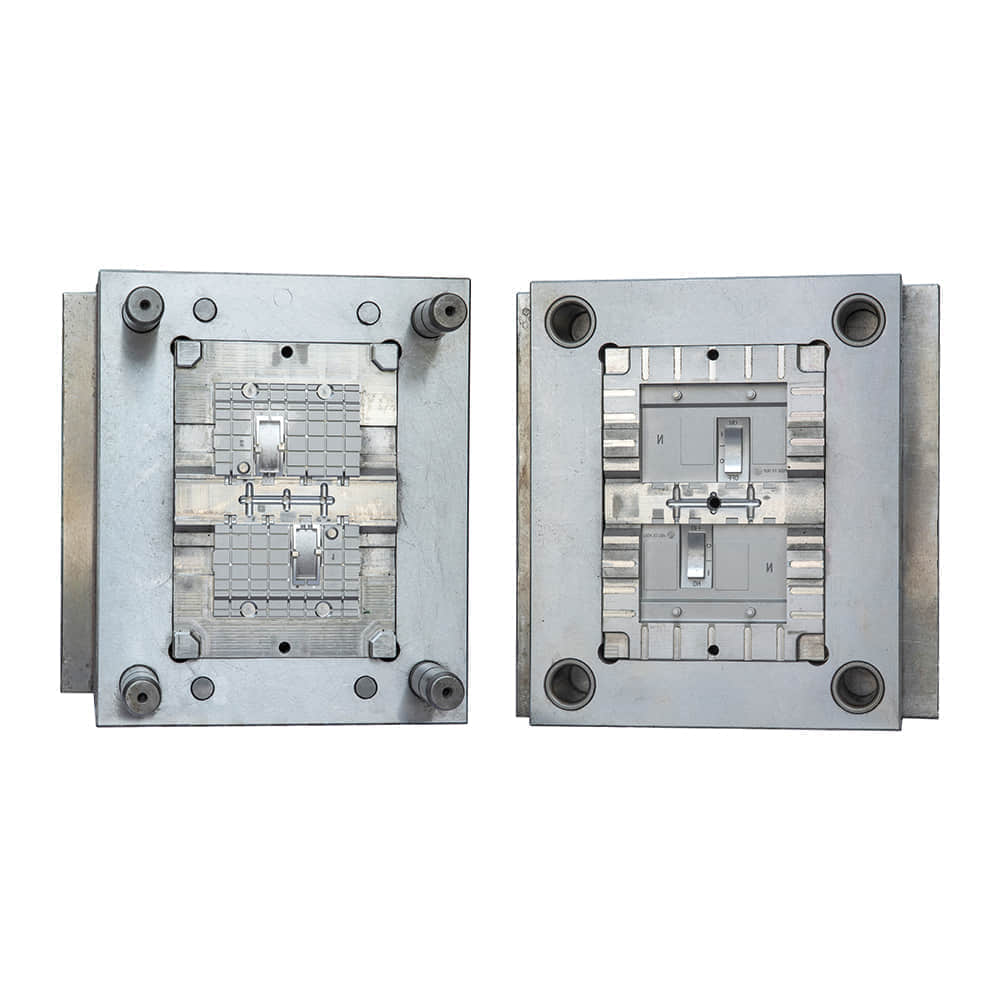

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create precise and complex parts. This technique has revolutionized production across various industries due to its efficiency and versatility. In this article, we will explore the advantages of injection molded parts and their diverse applications in modern manufacturing.

Understanding Injection Molding

Injection molding involves melting a material, typically a thermoplastic or thermosetting polymer, and injecting it into a mold cavity under high pressure. Once the material cools and solidifies, the mold is opened to eject the finished part. This process allows for the mass production of high-quality components with consistent dimensions and excellent surface finishes. Advantages of Injection Molded Parts