Date | 2024-09-05 12:06:41

In the fast-paced world of modern manufacturing, where speed, precision, and cost-effectiveness are paramount, Progressive Die stands as a cornerstone technology, driving productivity and innovation across diverse industries. This highly sophisticated tooling system not only revolutionizes the traditional stamping process but also underscores the evolution of manufacturing into an era of automation and efficiency.

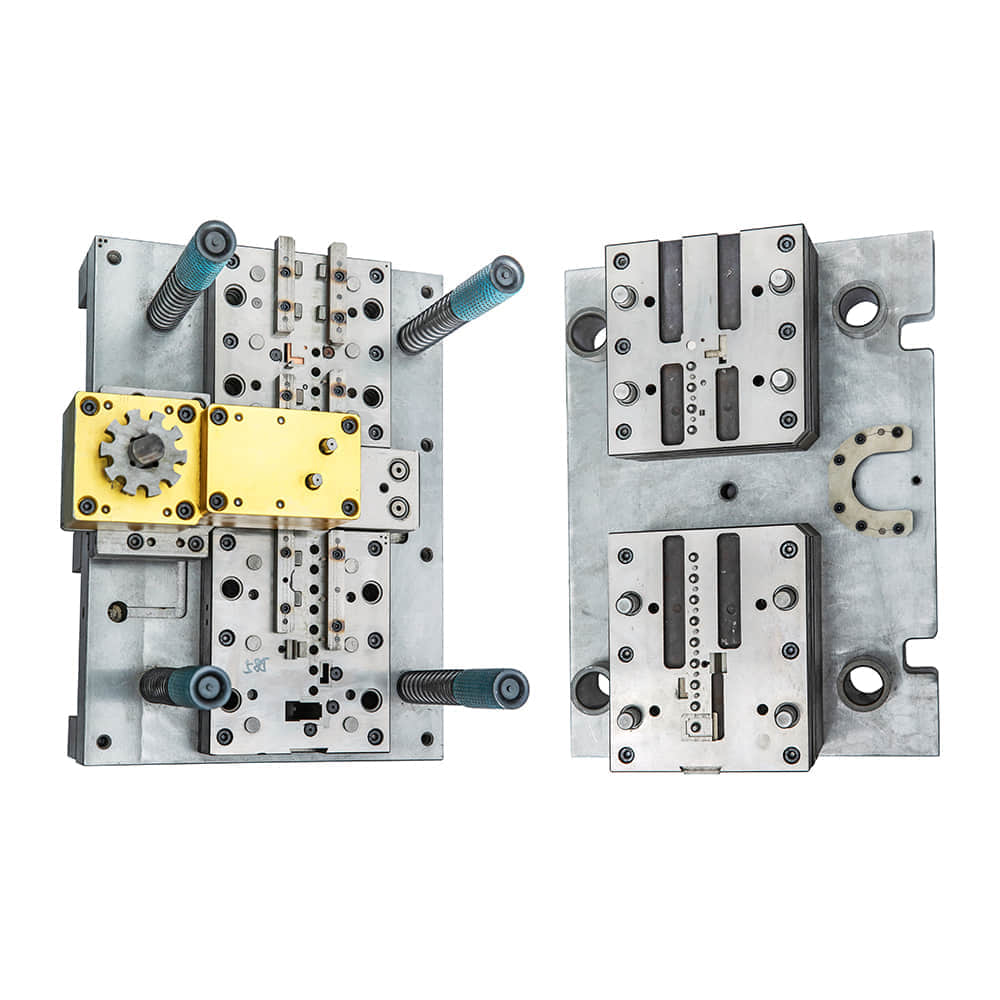

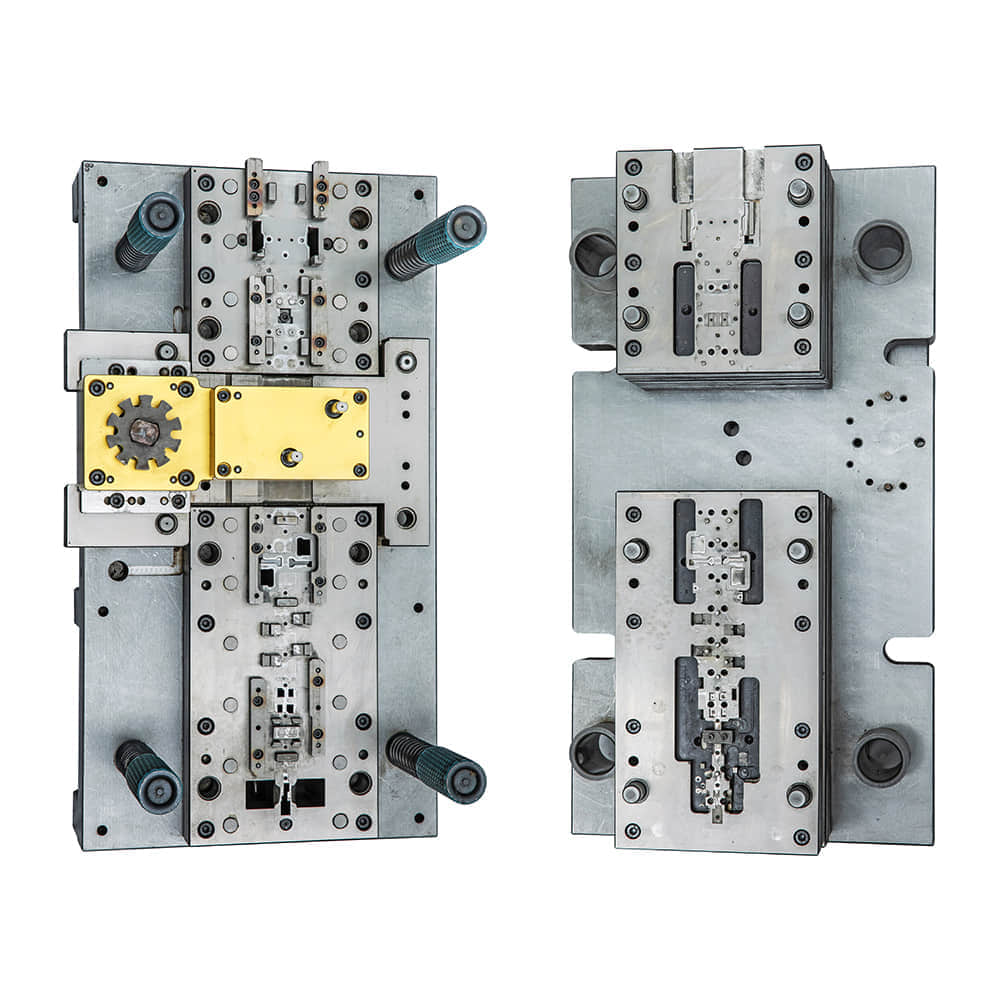

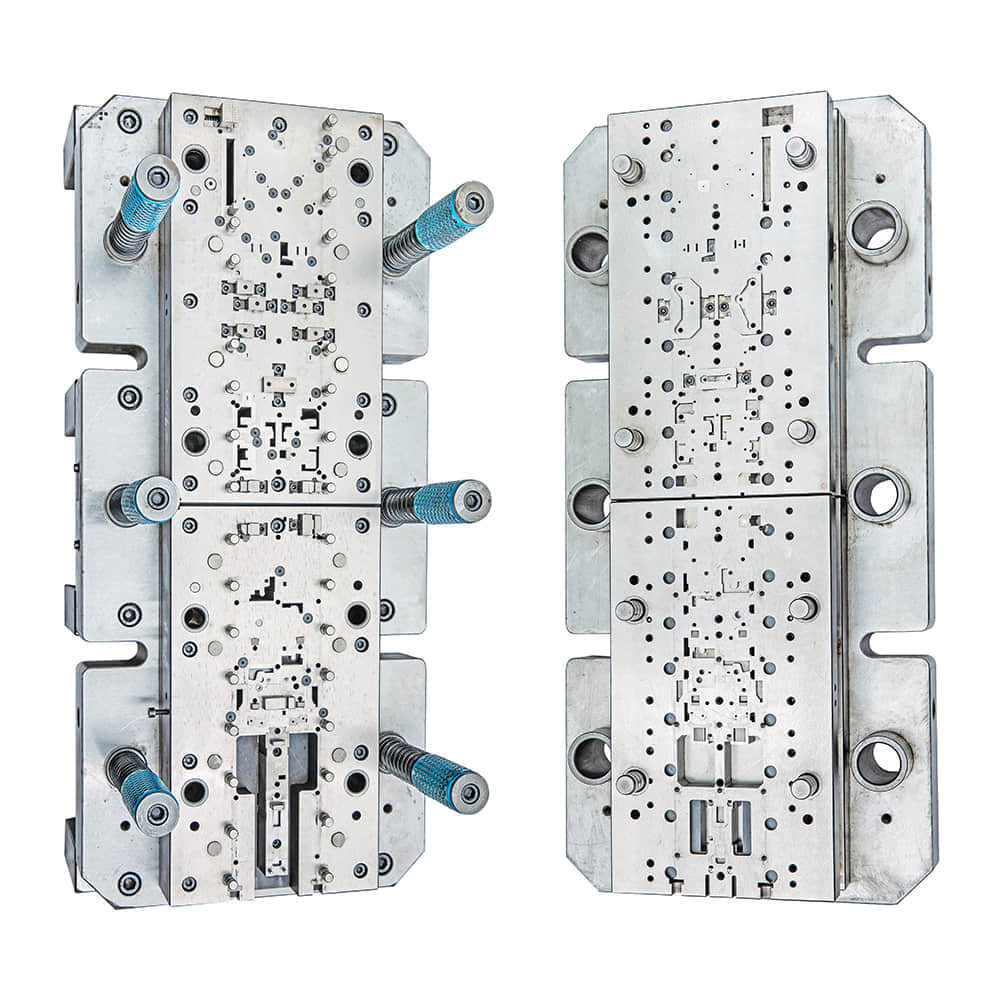

At its core, a Progressive Die is a complex mold arrangement that incorporates multiple stations or 'stages' within a single die set. Each stage performs a specific operation—from piercing, trimming, bending, to forming—on the workpiece as it moves progressively through the die on a conveyor or feeder system. This seamless transition between stages allows for the completion of multiple processing steps in a single press stroke, significantly reducing cycle time and enhancing production throughput.